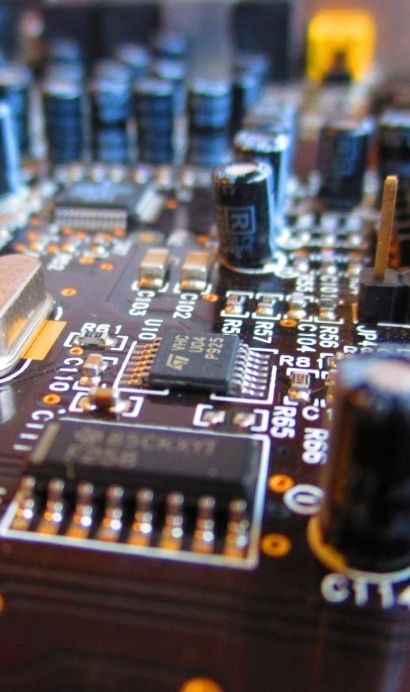

Design and manufacture of electronics on demand, R&D

In the field of electronics design and production services we anticipate the needs of a dynamically developing market. We offer production according to the documentation entrusted by the ordering party or the implementation of projects in a fuller scope, including design, construction, programming, production, implementation up to full technical support of the implemented solutions.

We have a professional design office and experienced IT and construction teams that guarantee our Clients the provision of professional technical services and the ability to carry out individual, one-time or untypical orders.

On the basis of modern laboratory and design facilities and our competences, we offer, among others, the following:

- design of multi-layer printed circuits (e.g. PCI-E, PCI 32bit, USB 2.0 cards),

- design of Xilinx FPGAs (VHDL),

- programming of ATMEL processors (AVR, AT91SAM, STM32),

- design of electrical diagrams (DC/DC converters, analog measurement systems, telecommunication interfaces, microprocessor systems, building automation devices, etc.),

- design of PCBs,

- application of protective coatings,

- deployment and testing of equipment,

- completion of elements,

- cabling,

- final mechanical assembly.

In construction processes we use OrCad, webpack xilinx ISE 10.1i., Max+Plus.

When designing electronic devices we focus not only on high quality, but also on the lowest possible production costs. Highly qualified staff allows us to guarantee the highest quality of production and the commissioned works. We cooperate with many manufacturers and distributors of electronic components and thanks to the large scale of orders we can guarantee our Clients very competitive prices

With our modern machine park, we can guarantee our Clients not only the highest quality production, but also a flexible approach to current needs: taking orders for prototype series, small or large production batches, short lead times. Design, production and assembly of electronics is carried out with the use of professional tools and devices, e.g:

- Mechatronika M70 automatic assembly machine with a video system with a capacity of 1600-2000 elements per hour. The ability to stack components from 0201 to 35 x 35 mm, QFP and BGA.

- Mechatronika M60 automatic assembly machine with a capacity of 1800 - 2200 elements per hour. The ability to stack elements from 0402 to 35 x 35 mm, QFP and BGA.

- Binder climate chamber model MKF115 designed for environmental tests with complex, variable climate profiles. The MKF BINDER environmental simulation chamber is ideally suited for all types of low and high temperature tests carried out in accordance with the temperature and climatic resistance test methods described in the current DIN and IEC standards. It allows testing in the temperature range from -40 to +180 degrees C. Relative humidity range from 10 to 98%.

- Re-flow soldering furnace Mechatronika type MR260. The MR260 convection tunnel kiln is a universal device for re-flow soldering of SMD components on printed circuit boards. It has a dynamic heating system ensuring high temperature stability in individual zones.

- Uniprint's automatic silk-screen printer model PM GO3V with automatic paste application process, monitored with the use of cameras.

- The Mechatronika MM600 mounting manipulator. It is used for small series and prototype production. The device ensures high efficiency and reliability of the stacking process thanks to the built-in system of checking the correctness of the stacking of the elements (eliminates incorrect stacking or omissions).

- MiniContac RS devices for galvanization of printed circuit board passages using the “black hole” process and galvanic reinforcement of copper surfaces. The minimum diameter of the hole for coating is 0.2 mm. The device can be used for double-sided and multi-layer printed circuit boards.

- ProtoMatu LPKF S63 for milling prototype PCB boards, single and double sided. With a travel speed of 150 mm/s and a motor speed of 40,000 to 100,000 rpm, ProtoMat S63 is able to produce high quality and complex PCBs with exceptional speed and professionalism. This device achieves the highest precision at a resolution of 0.25 µm.

- Professional CNC milling and engraving machine MFG4025P for milling, engraving, cutting and drilling in soft metals, plastics and wood. The working area X/Y is 400 x 250 mm, the working area for the Z axis is 140 mm.

- Ultrasonic cleaner.

- Mantis Elite microscope for optical inspection.

We also design templates for soldering paste.

In order to satisfy our Clients, we make every effort to ensure that our resources meet the highest quality standards and the latest technical trends. All design, production and service processes are subject to cyclic, rigorous quality audits.